BlocD8 - DCC Block Detector Application Information

Block Detector:

The BlocD8 can be used in most DCC systems in a stand-alone mode or in a network with other devices. In a network the BlocD8 serial bus (Digitrax LocoNet® compatible) is used. It can be used with Team Digital signal products and with computer software like JMRI.

It is designed to sense high frequency DCC AC current and will not work with DC current or 60 cycle AC current.

Sensitivity Issues:

There are several reasons why the BlocD8 may indicate a block is occupied when in fact there is no engine or rolling stock in the block.

A LED or some kind of indicator that is powered from the track.

A frog power controller.

A reverse loop controller.

High humidity conditions can cause a problem. Perhaps the ballast is damp for some reason. Water can act like a resistor between the rails. There can be enough distributed capacitance in the DCC wires to cause a small amount of current to flow and thus causing a false indication. To keep the capacitance to a minimum, keep the the block feed wire or any of the block track feeder wires from running right next to other wires for long distances. Do not twist the block feed wire with another wire.

The BlocD8 has two potentiometers to adjust sensitivity. Turning the pot CCW will increase the sensitivity. If the pot is turned fully CCW there may be false block detection. Passing the feed wire through each sensor two or three (maximum) times will increase the sensor output (sensitivity). If desired, the sensitivity pots can be adjusted (less sensitive) to make the over all sensitivity the same. This scheme will cause the BlocD8 to be less susceptible to false indications due to wire routing near the BlocD8. This will not solve problems due to issues mentioned above.

Sensitivity Recommendations and limits:

The maximum recommended number of feed wire passes though the sensor is three (3). The maximum sensor current is 3 amps. This means the maximum current in the block that the sensor is detecting (not short circuit current). The circuit breaker trip point recommendation is less than 5 amps and as close to 3 amps as possible for blocks where the BlocD8 is detecting. Less than 3 amps is certainly OK but may cause issues with sound equipped locomotives. In general this is good practice for HO scale to protect engines and other rolling stock that could cause a short.

Wiring:

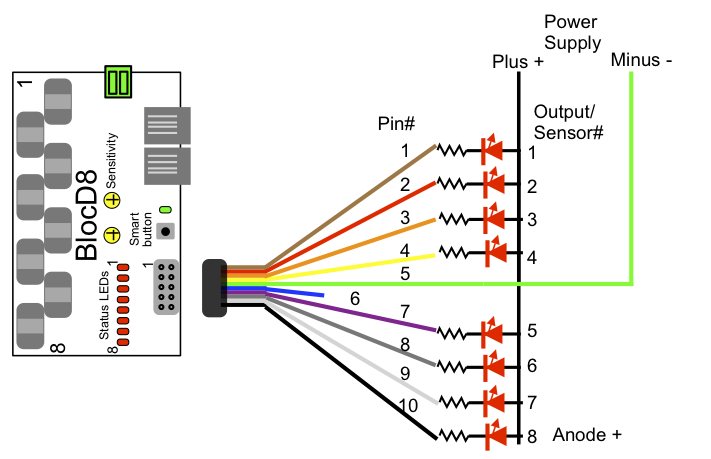

See a picture for suggested block wire routing and connection to the BlocD8.

Recommended wire size is 18 gauge stranded max or better 20 gauge stranded to pass through the sensors. 20 gauge copper wire can handle about 6 amps. Some older manuals say 16 gauge max. which is probably to large (stiff). Stiff wire can easily cause damaged sensors.

Below is a diagram showing how to connect LEDs to the BlocD8 outputs. The LED current limiting resistor value will vary based on the power supply voltage. This power supply must be separate and isiloated from the supply that powers the BlocD8.

System Issues:

The BlocD8 serial bus is Digitrax LocoNet® compatible. It is not compatible with the NCE throttle bus. This does not mean it will not work in a NCE system.

The BlocD8 serial bus is Digitrax LocoNet® compatible, however, there seems to be some issues in a Uhlenbrock Intellibox system. To avoid problems power the BlocD8 with a separate isolated 12V DC power supply. Isolated means it can not have the same ground as any other device.